HARDENED & TEMPERED STRIP STEEL

Top Quality That Drives Customer Satisfaction and Profits.

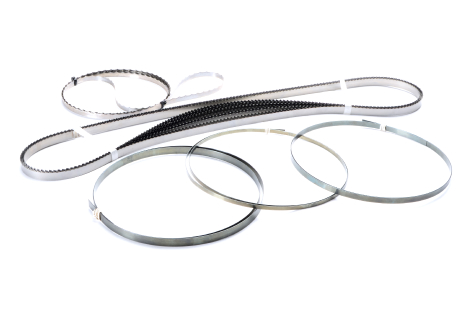

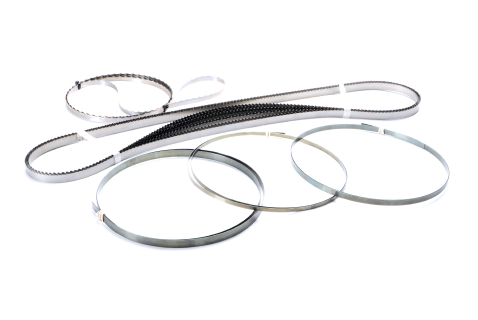

Product Image

Product Division

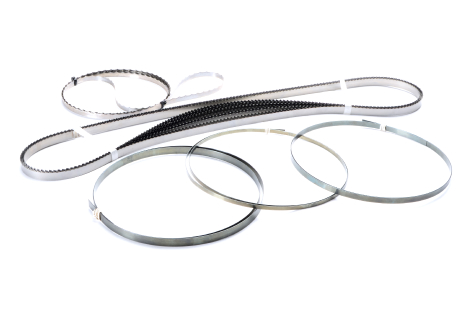

Our hardened and tempered strip steel is ideal for items such as saw blades, surgical blades, and auto parts. Known for its durability, perfect for a wide range of applications. Designed to withstand tough tasks, excels in both industrial and manufacturing environments.

Carbon Tool Steel Product

SK-2(SK120M) -

Razor blade, Cutlery

SK-3(SK105M) -

Hack saws, Cutlery, Springs

SK-4(SK95M) -

Measuring tape, Razor blade, Springs, Cutlery, Knitting needles

SK-5(SK85M) -

Gauges, Springs, Cutlery, Clutch parts, Band saw and Hack saw, Circular saws

SK2MCR4 -

Razor blades, Cutlery

Carbon Steel Product

S30CM -

Retainers

S35CM(SAE1035) -

Office-equipment parts, Friction plates

S45CM(SAE1045) -

Clutch parts, Chain parts, Retainer, Washers

S50CM(SAE1050) -

Safety shoes, Measuring tape, Chain parts, Springs, Clutch parts, Washers, Safety buckles

S55CM(SAE1055) -

Safety buckles, Springs, Can openers, Thomson blades

S60CM(SAE1060) -

Chain part, Woodworking tool part, Springs

S65CM(SAE1065) -

Safety shoes, Clutch parts, Springs, Washers

S70CM(SAE1070) -

Washers, Hand saws for woodworking, Office-equipment parts, Springs

S75CM(SAE1074) -

Circlips, Horn Diaphragm, Clutch parts, Washers, Springs

Alloy Tool Steel Product

SKS-5M -

Cutlery, Round saws, Band saws for woodworking and lumbering

SKS-51M -

Cutlery, Round saws, Band saws for woodworking and lumbering

Spring Steel Product

50CRV4(SUP10) -

Machinery springs, Torsion bar

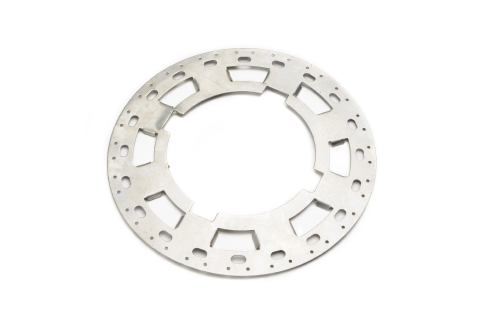

Application Product

Strip Steel for Automobile Industry

Specification

| THICKNESS | 0.1 ~ 4.0 mm |

|---|---|

| WIDTH | 5.0 - 450 mm |

| HARDNESS | HV 300 ~ 600 |

| STRUCTURE | Bainite, Tempered Martensite |

| HARDNESS TOLERANCE | ± HV 20 (Special ± HV 10) |

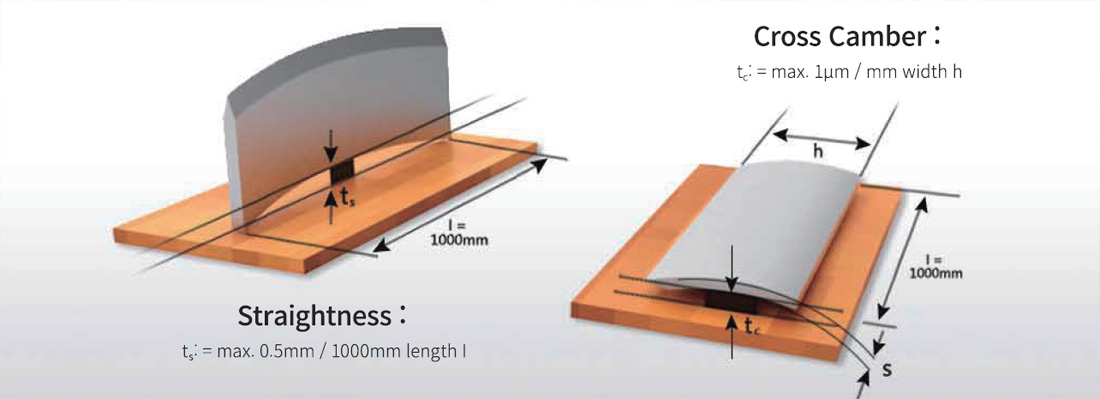

| STRAIGHTNESS | Max 0.5mm / 1,000 mm length |

| CROSS CAMBER | Max 3μm / mm Width (Special Max 1μm/ mm Width) |

| SURFACE COLOR | Unpolished blue, Bright, Polished blue, Polished white, Polished yellow |

| EDGE FINISH | Slit edge, Deburred edge, Round edge, chamfered edge, Square edge |

| INNER DIAMTER | MIN. 300 ~ 600mm |

| OUTER DIAMETER | MAX. 1,800mm |

Application

Strip Steel for Saw Blade/Others

Specification

| THICKNESS | 0.1 ~ 4.0 mm |

|---|---|

| WIDTH | 5.0 - 450 mm |

| HARDNESS | HV 300 ~ 600 |

| STRUCTURE | Bainite, Tempered Martensite |

| HARDNESS TOLERANCE | ± HV 20 (Special ± HV 10) |

| STRAIGHTNESS | Max 0.5mm / 1,000 mm length |

| CROSS CAMBER | Max 3μm / mm Width (Special Max 1μm/ mm Width) |

| SURFACE COLOR | Unpolished blue, Bright, Polished blue, Polished white, Polished yellow |

| EDGE FINISH | Slit edge, Deburred edge, Round edge, chamfered edge, Square edge |

| INNER DIAMTER | MIN. 300 ~ 600mm |

| OUTER DIAMETER | MAX. 1,800mm |

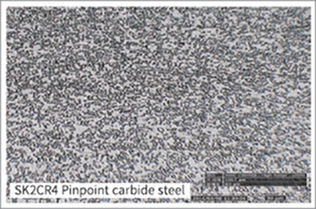

Microstructure

Fully spheroidized pin-point carbides

Free of carbide network or lamellar pearlite and free of carbide alignment, uniformly distributed in a ferrite matrix.

Carbide size is less than 1-micron diameter, maximum carbide is not exceeding 3 microns, carbide spacing shall not exceed 4 microns.

Application

Shaving Strip Steel

Precision Edge Finishing for Every Application

We offer high-precision edge finishing to meet the specific requirements of every application. Whether the edge needs to be deburred, rounded, chamfered, square, bevel shaved, or bevel shaved with high-frequency treatment, we can deliver exact edge geometries with exceptional accuracy.

Upon request, we tailor the edge profile of our strip steels to precisely match customer specifications.

| FINISH TYPE | DEFINITION | APPLICATION | IMAGE |

|---|---|---|---|

| Slit edge | sharp edged with slitting burrs left on | left spring |  |

| Deburred edge | slit edges from which burrs have been removed | left spring |  |

| Round edge | edged rounded | power spring |  |

| Chamfered edge | square edge with round corner | saws and blades |  |

| Square edge | sharp-cornered square edges | band saws |  |

| Bevel shaved edge | sharp-bevel | rotary rule |  |

| Bevel shaved edge + High frequency | sharp-bevel with high frequency of edge | rotary rule |  |

Mechanical Property

Available Dimension

Specification

| THICKNESS | 0.1 ~ 4.0 mm |

|---|---|

| WIDTH | 5.0 - 450 mm |

| HARDNESS | HV 300 ~ 600 |

| STRUCTURE | Bainite, Tempered Martensite |

| HARDNESS TOLERANCE | ± HV 20 (Special ± HV 10) |

| STRAIGHTNESS | Max 0.5mm / 1,000 mm length |

| CROSS CAMBER | Max 3μm / mm Width (Special Max 1μm/ mm Width) |

| SURFACE COLOR | Unpolished blue, Bright, Polished blue, Polished white, Polished yellow |

| EDGE FINISH | Slit edge, Deburred edge, Round edge, chamfered edge, Square edge |

| INNER DIAMTER | MIN. 300 ~ 600mm |

| OUTER DIAMETER | MAX. 1,800mm |

Unit Cutting Strip Steel

Specification

| THICKNESS | 0.5 ~ 2.0 mm |

|---|---|

| WIDTH | 10 ~ 100 mm |

| STRAIGHTNESS | Max 0.5mm / 1,000mm length |

| CROSS CHAMBER | Max. 3㎛ / mm Width (Special Max. lum / mm Width) |

Specification for Oscillating

| THICKNESS | ~ 2.0 mm |

|---|---|

| WIDTH | ~ 70 mm |

Technical information

Packing

Specification

| IN DIA METER | 400 ~ 510 mm |

|---|---|

| OUT DIA METER(MAX) | ~ 2,000 mm |

| WEIGHT (MAX) | ~ 2,000 kg |

| REMARK | In coil, Wrapped |